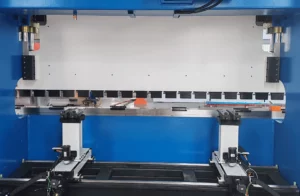

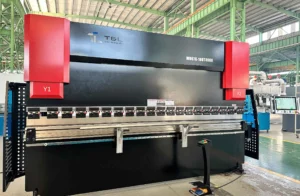

PD-17041 CNC Hybrid Servo Press Brake

Model: PD-17041

Brand Name: TLBEND

Highlights:

- Simple cylinder interface with no external piping

- Energy-saving and noise reduction

- High efficiency working speed

- High-precision components

Applications:

- Steel Structures

- Elevators

- Furniture Manufacturing

Technical Parameter

| Model | Unit | PD-17041 |

|---|---|---|

| Bending Force | KN | 1700 |

| Bending Length | mm | 4100 |

| Distance Between Uprights | mm | 3600 |

| Throat Depth | mm | 450 |

| Ram Stroke | mm | 230 |

| Opening Height | mm | 510 |

| Ram max.speed | ||

| Approaching | mm/s | 180 |

| Working | mm/s | 5.0-12 |

| Returning | mm/s | 180 |

| Main Power | KW | 7.5 x 2 |

| Oil Tank Volume | L | 90 x 2 |

| Dimension | mm | 4500 x 2300 x 3150 |

| Weight | kg | 13500 |

| Warranty | Years | 2 |

Specifications apply to standard models. T&L reserves the right to adjust data without notice.

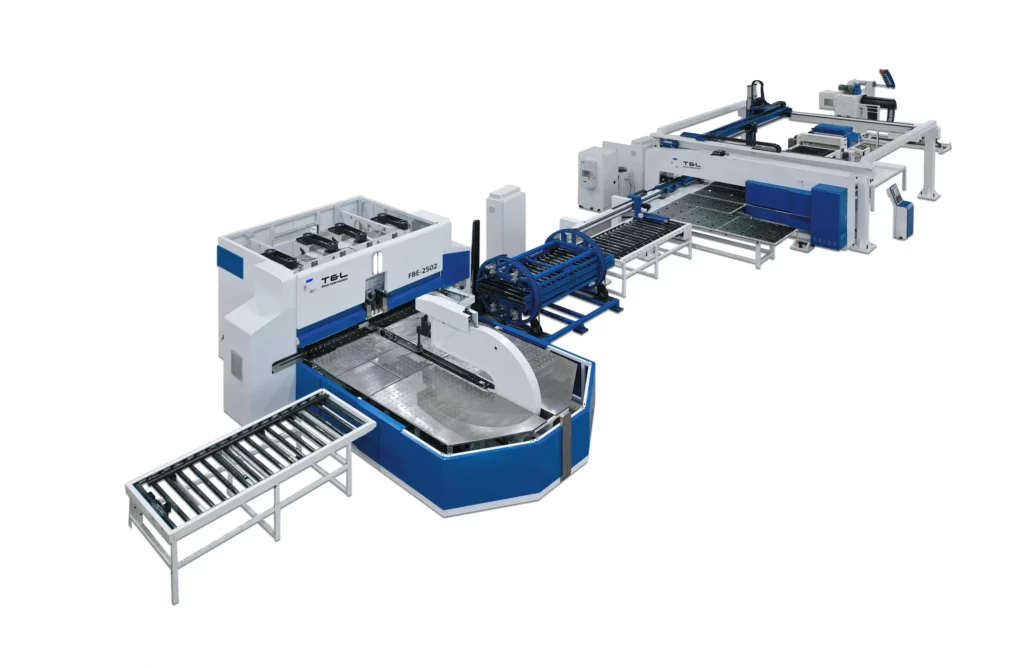

Machine Configuration Overview

Servo Drive System

Innovative servo drive reduces energy use and noise, ideal for efficient, compact operations needing reliable drive mechanisms without complex external piping.

Multi-Axis Backgauge CNC Control

Six-axis CNC (X1, X2, Y1, Z1, Z2, R1, R2) offers 0.02mm positioning accuracy, suitable for precise bending applications demanding exceptional repeatability.

User-Friendly Control System

The DELEM DA66T controller provides an intuitive interface, simplifying operation and maximizing efficiency, ideal for users who prioritize streamlined functionality and productivity in their production processes.

Heat Treatment Machine Body

Annealing Structure machine frame will go through heat treatment Over 600°C to relieve the stress.

Machine Configuration Overview

Trust T&L: Leading China Sheet Metal Machine Manufacturer

Reliable Imported Components

Advanced Manufacturing Capabilities

Broad Product Line Coverage

Comprehensive Customization Capabilities

Efficient Multi-step Quality Inspections

High-Value Pricing with Superior Quality

7-30 days Rapid Delivery

1-Hour Response & 12-Hour Resolution

Hear from Our Global Partners

“The team at T&L is always quick to respond, often within an hour. Knowing they’re there to solve any issue keeps our operations running smoothly—we rely on their support.”

Alexei PetrovRussia

“T&L’s attention to our production needs has been exceptional. Their reliable equipment and quick support help us meet deadlines and keep our processes running seamlessly.”

Fatima Al-SalemSaudi Arabia

“Partnering with T&L has genuinely elevated our business. The quick delivery and dependable support allow us to stay competitive here in the Middle East, where our clients value both quality and consistency.”

John CarterUnited Arab Emirates

“We needed a custom solution for high-precision bending, and T&L delivered. The machines are robust and perfectly tailored to our specs, saving us both time and cost in production.”

Lucas FischerGermany

Previous

Next